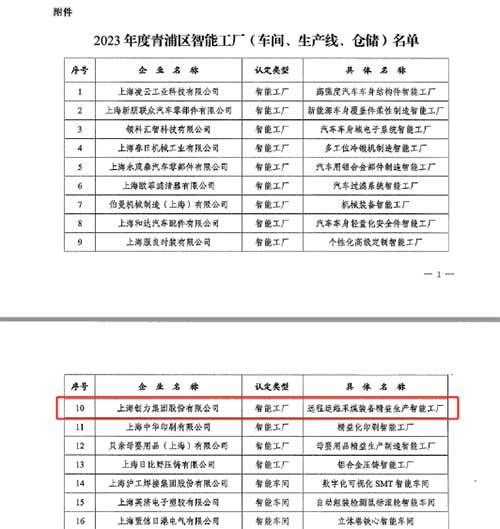

In line with the strategic deployment for the comprehensive digital transformation of Shanghai and to accelerate the intelligent upgrading of enterprises as well as the construction of smart factories, the Qingpu District Economic Commission recently announced the list of 2023 Qingpu District's Smart Factories. Shanghai Chuangli Group was successfully selected for this prestigious list, owing to its outstanding innovation capabilities and technical proficiency in the field of smart manufacturing. On May 24, the district's Economic Commission presented awards to the companies that were recognized as 2023 Qingpu District's Smart Factories.

Amid the wave of digital technology development, Shanghai Chuangli Group has actively responded to national initiatives of the "Made in China 2025," the "14th Five-Year Plan for the Development of Smart Manufacturing," and the "Industrial Internet" action plan. Guided by the principle of "Digital Innovation," the group has continuously increased its investment in technological upgrades; with the aim of lean production, it has accelerated the construction of lean management in factories, thus realizing the development of digital transformation.

2023 marked a significant year for the digital transformation of Shanghai Chuangli Group. The company established a "Digital Innovation" smart manufacturing project team and set up a digital collaborative design application scenario. It implemented an advanced MRP (Material Requirements Planning) scheduling system to quickly respond to customer demands. A paperless, full-process production control and management system was introduced, featuring digital dashboards that display comprehensive production metrics. The group also adopted a data-driven digital twin visualization management system for production lines and core engineering operations, enabling real-time AI-powered visual safety management across the entire plant, production lines, and overall engineering projects. Additionally, it has implemented a material batch management system, which includes barcode scanning for warehouse entry and exit, and a traceable 2D code management system to enhance the traceability and efficiency of the supply chain.

In the factory design phase, Shanghai Chuangli leverages digital twin technology to efficiently plan the assembly plants and achieve digital delivery. Throughout the construction of the smart factory, the company consistently follows the 136N Digital Innovation Blueprint. By promoting the application of digital scenarios such as ERP (Enterprise Resource Planning), SRM (Supplier Relationship Management), WMS (Warehouse Management System), and equipment operation and maintenance platforms, Shanghai Chuangli has gradually established a digital application ecosystem with its upstream/downstream customers and suppliers. This greatly fosters collaborative progress and win-win cooperation between the group and its domestic and international partners.

Shanghai Chuangli Group will continue to deepen its expertise in smart manufacturing, advancing towards a future that is safer, more efficient, greener, and smarter. This commitment aims to inject significant momentum into the high-quality development of the coal machinery manufacturing industry.